SHY系列长轴液下泵

SHY液下泵产品概述

SHY系列长轴液下泵属于单级单吸立式泵。是根据市场需求,自主设计开发的新型、节能环保产品,用于输送中性或有腐蚀性的清洁液体。特别适用于:污水处理、水泥厂、发电厂、石油化工等行业。

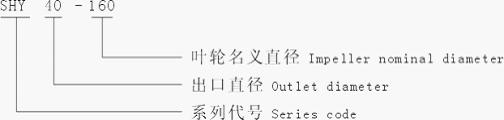

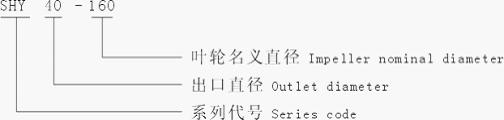

SHY液下泵型号意义

SHY液下泵性能参数

|

型号

|

转速

(r/min)

|

流量

(m3/h)

|

扬程

(m)

|

比重1.0

|

比重1.35

|

比重1.85

|

|

电机功率 KW

|

|

SHY32-125

|

2900

|

12.5

|

20

|

2.2

|

3.0

|

4.0

|

|

1450

|

6.3

|

5.0

|

0.55

|

0.55

|

0.75

|

|

SHY32-125A

|

2900

|

11.3

|

16.4

|

1.5

|

2.2

|

3.0

|

|

1450

|

5.7

|

4.1

|

0.55

|

0.55

|

0.55

|

|

SHY32-160

|

2900

|

12.5

|

32

|

4.0

|

5.5

|

7.5

|

|

1450

|

6.3

|

8.0

|

0.75

|

0.75

|

1.1

|

|

SHY32-160A

|

2900

|

11.3

|

26.4

|

3.0

|

4.0

|

5.5

|

|

1450

|

5.7

|

6.6

|

0.55

|

0.75

|

1.1

|

|

SHY32-160B

|

2900

|

10.5

|

22

|

2.2

|

3.0

|

4.0

|

|

1450

|

5.25

|

5.5

|

0.55

|

0.55

|

0.75

|

|

SHY32-200

|

2900

|

12.5

|

50

|

7.5

|

11

|

11

|

|

1450

|

6.3

|

12.5

|

1.1

|

1.5

|

2.2

|

|

SHY32-200A

|

2900

|

11.3

|

41

|

5.5

|

7.5

|

11

|

|

1450

|

5.7

|

10.3

|

1.1

|

1.5

|

1.5

|

|

SHY32-200B

|

2900

|

10.5

|

35.5

|

4.0

|

5.5

|

7.5

|

|

1450

|

5.25

|

9.0

|

0.75

|

1.1

|

1.5

|

|

SHY32-250

|

2900

|

12.5

|

80

|

11

|

15

|

22

|

|

1450

|

6.3

|

20

|

2.2

|

3.0

|

4.0

|

|

SHY32-250A

|

2900

|

11.7

|

70

|

11

|

15

|

18.5

|

|

1450

|

5.9

|

17.5

|

1.5

|

2.2

|

3.0

|

|

SHY32-250B

|

2900

|

11

|

62

|

11

|

11

|

15

|

|

1450

|

5.5

|

15.5

|

1.5

|

2.2

|

3.0

|

|

SHY50-125

|

2900

|

25

|

20

|

3.0

|

4.0

|

5.5

|

|

1450

|

12.5

|

5.0

|

0.55

|

0.75

|

1.1

|

|

SHY50-125A

|

2900

|

22.7

|

16.5

|

3.0

|

4.0

|

5.5

|

|

1450

|

11.3

|

4.1

|

0.55

|

0.75

|

0.75

|

|

SHY50-125B

|

2900

|

20

|

13

|

2.2

|

3.0

|

4.0

|

|

1450

|

10

|

3.2

|

0.55

|

0.55

|

0.75

|

|

SHY50-160

|

2900

|

25

|

32

|

5.5

|

7.5

|

11

|

|

1450

|

12.5

|

8.0

|

1.1

|

1.5

|

1.5

|

|

SHY50-160A

|

2900

|

22.7

|

26.5

|

4.0

|

5.5

|

7.5

|

|

1450

|

11.3

|

6.6

|

0.75

|

1.1

|

1.5

|

|

SHY50-160B

|

2900

|

21.0

|

22.5

|

4.0

|

5.5

|

7.5

|

|

1450

|

10.5

|

5.6

|

0.55

|

0.75

|

1.1

|

|

SHY40-200

|

2900

|

25

|

50

|

11

|

11

|

15

|

|

1450

|

12.5

|

12.5

|

1.5

|

2.2

|

3.0

|

|

SHY40-200A

|

2900

|

23.4

|

44

|

7.5

|

11

|

15

|

|

1450

|

11.7

|

11

|

1.1

|

1.5

|

2.2

|

|

SHY40-200B

|

2900

|

21.0

|

36

|

5.5

|

7.5

|

11

|

|

1450

|

10.5

|

9.0

|

1.1

|

1.1

|

1.5

|

|

SHY40-250

|

2900

|

25

|

80

|

15

|

22

|

30

|

|

1450

|

12.5

|

20

|

3.0

|

4.0

|

5.5

|

|

SHY40-250A

|

2900

|

23.4

|

70

|

15

|

18.5

|

30

|

|

1450

|

11.7

|

17.5

|

2.2

|

3.0

|

4.0

|

|

SHY40-250B

|

2900

|

22

|

61.8

|

11

|

15

|

22

|

|

1450

|

11

|

15.5

|

2.2

|

3.0

|

4.0

|

|

SHY40-315

|

1450

|

12.5

|

32.0

|

5.5

|

7.5

|

7.5

|

|

SHY40-315A

|

1450

|

11.7

|

27.4

|

4.0

|

5.5

|

7.5

|

| |

|

|

|

|

|

|

SHY40-315B

|

1450

|

11

|

24.1

|

3.0

|

4.0

|

5.5

|

| |

|

|

|

|

|

|

SHY40-315C

|

2900

|

20.5

|

84.1

|

18.5

|

22

|

30

|

|

1450

|

10.3

|

21

|

3.0

|

4.0

|

5.5

|

|

SHY65-125

|

2900

|

50

|

20

|

5.5

|

7.5

|

11

|

|

1450

|

25

|

5

|

1.1

|

1.5

|

1.5

|

|

SHY65-125A

|

2900

|

45.3

|

16.5

|

4.0

|

5.5

|

7.5

|

|

1450

|

22.6

|

4.1

|

0.75

|

1.1

|

1.5

|

|

SHY65-125B

|

2900

|

42

|

14.5

|

4.0

|

5.5

|

7.5

|

|

1450

|

21

|

3.6

|

0.75

|

1.1

|

1.5

|

|

SHY65-160

|

2900

|

50

|

32

|

11

|

11

|

15

|

|

1450

|

25

|

8

|

1.5

|

1.5

|

2.2

|

|

SHY65-160A

|

2900

|

45.4

|

26.4

|

7.5

|

11

|

15

|

|

1450

|

22.7

|

6.6

|

1.1

|

1.5

|

2.2

|

|

SHY65-160B

|

2900

|

40.5

|

21.5

|

5.5

|

7.5

|

11

|

|

1450

|

20.3

|

5.4

|

1.1

|

1.5

|

1.5

|

|

SHY50-200

|

2900

|

50

|

50

|

15

|

18.5

|

30

|

|

1450

|

25

|

12.5

|

2.2

|

3

|

4

|

|

SHY50-200A

|

2900

|

45.4

|

41

|

11

|

15

|

22

|

|

1450

|

22.7

|

10.3

|

1.5

|

2.2

|

3

|

|

SHY50-200B

|

2900

|

40.5

|

32.5

|

7.5

|

11

|

15

|

|

1450

|

20.3

|

2.1

|

1.5

|

2.2

|

2.2

|

|

SHY50-250

|

2900

|

50

|

80

|

30

|

37

|

45

|

|

1450

|

25

|

20

|

4.0

|

5.5

|

7.5

|

|

SHY50-250A

|

2900

|

46.9

|

70.5

|

22

|

30

|

37

|

|

1450

|

23.45

|

17.6

|

3

|

4

|

5.5

|

|

SHY50-250B

|

2900

|

44

|

62.2

|

18.5

|

30

|

37

|

|

1450

|

22

|

15.6

|

3

|

4

|

5.5

|

|

SHY50-315

|

1450

|

25

|

32

|

7.5

|

11

|

11

|

|

SHY50-315A

|

1450

|

23.45

|

28

|

5.5

|

7.5

|

11

|

|

SHY50-315B

|

1450

|

22

|

24.5

|

5.5

|

7.5

|

11

|

|

SHY50-315C

|

2900

|

39

|

77

|

22

|

30

|

45

|

|

1450

|

19.5

|

19.5

|

3

|

4

|

5.5

|

|

SHY80-125

|

2900

|

100

|

20

|

11

|

15

|

18.5

|

|

1450

|

50

|

5

|

1.5

|

2.2

|

3

|

|

SHY80-125A

|

2900

|

91.8

|

16.8

|

7.5

|

11

|

15

|

|

1450

|

45.9

|

4.2

|

1.5

|

2.2

|

3

|

|

SHY80-160

|

2900

|

100

|

32

|

15

|

22

|

30

|

|

1450

|

50

|

8

|

2.2

|

3

|

4

|

|

SHY80-160A

|

2900

|

91

|

26.5

|

15

|

18.5

|

22

|

|

1450

|

45.5

|

6.6

|

2.2

|

2.2

|

3

|

|

SHY80-160B

|

2900

|

78.5

|

21.8

|

7.5

|

11

|

15

|

|

1450

|

39.3

|

10.92

|

1.5

|

2.2

|

2.2

|

|

SHY65-200

|

2900

|

100

|

50

|

30

|

37

|

45

|

|

1450

|

50

|

12.5

|

4.0

|

5.5

|

7.5

|

|

SHY65-200A

|

2900

|

91

|

41.5

|

18.5

|

30

|

37

|

|

1450

|

45.5

|

10.4

|

3.0

|

4.0

|

5.5

|

|

SHY65-200B

|

2900

|

86.5

|

35

|

15

|

22

|

30

|

|

1450

|

43.3

|

8.8

|

2.2

|

3.0

|

4.0

|

|

SHY65-250

|

2900

|

100

|

80

|

45

|

55

|

75

|

|

1450

|

50

|

20

|

5.5

|

7.5

|

11

|

|

SHY65-250A

|

2900

|

93.5

|

70

|

37

|

45

|

75

|

|

1450

|

46.8

|

17.5

|

5.5

|

7.5

|

11

|

|

SHY65-250B

|

2900

|

27.8

|

61.7

|

30

|

45

|

55

|

|

1450

|

43.9

|

15.4

|

4.0

|

5.5

|

7.5

|

|

SHY65-315

|

1450

|

50

|

32

|

11

|

15

|

18.5

|

|

SHY65-315A

|

1450

|

46.8

|

28

|

11

|

11

|

15

|

|

SHY65-315B

|

1450

|

43.9

|

24.3

|

7.5

|

11

|

15

|

|

SHY65-315C

|

2900

|

83

|

86.1

|

45

|

55

|

75

|

|

1450

|

41.5

|

21.5

|

5.5

|

7.5

|

11

|

|

SHY100-200

|

2900

|

200

|

50

|

4.5

|

75

|

90

|

|

1450

|

100

|

12.5

|

7.5

|

11

|

15

|

|

SHY100-200A

|

2900

|

182

|

41.4

|

37

|

45

|

75

|

|

1450

|

91

|

10.4

|

5.5

|

7.5

|

11

|

|

SHY100-200B

|

2900

|

166

|

34

|

30

|

37

|

55

|

|

1450

|

83

|

8.5

|

4.0

|

5.5

|

7.5

|

|

SHY100-250

|

2900

|

200

|

80

|

75

|

110

|

132

|

|

1450

|

100

|

20

|

11

|

15

|

18.5

|

|

SHY100-250A

|

2900

|

186.5

|

69.5

|

75

|

90

|

110

|

|

1450

|

93.5

|

17.5

|

11

|

11

|

15

|

|

SHY100-250B

|

2900

|

175.5

|

61.5

|

55

|

75

|

110

|

|

1450

|

87.8

|

15.4

|

7.5

|

11

|

15

|

|

SHY100-250C

|

2900

|

159

|

50.5

|

45

|

55

|

75

|

|

1450

|

79.5

|

12.6

|

5.5

|

7.5

|

11

|

|

SHY100-315

|

1450

|

100

|

32

|

18.5

|

22

|

30

|

|

SHY100-315A

|

1450

|

93.5

|

27.5

|

15

|

18.5

|

30

|

|

SHY100-315B

|

1450

|

87.8

|

24.5

|

15

|

18.5

|

22

|

|

SHY100-315C

|

2900

|

164.5

|

84.5

|

75

|

110

|

132

|

|

1450

|

82.3

|

21.5

|

11

|

15

|

18.5

|

|

SHY100-400

|

1450

|

100

|

50

|

30

|

45

|

55

|

|

SHY100-400A

|

1450

|

93

|

43.2

|

30

|

37

|

45

|

|

SHY100-400B

|

1450

|

87.8

|

38.5

|

22

|

30

|

45

|

|

SHY100-400C

|

1450

|

81.5

|

33.2

|

18.5

|

30

|

37

|

|

SHY125-250

|

1450

|

200

|

20

|

18.5

|

30

|

37

|

|

SHY125-250A

|

1450

|

182

|

16.5

|

15

|

18.5

|

30

|

|

SHY125-250B

|

1450

|

170

|

14.5

|

11

|

15

|

22

|

|

SHY125-315

|

1450

|

200

|

32

|

30

|

37

|

55

|

|

SHY125-315A

|

1450

|

182

|

25.5

|

22

|

30

|

45

|

|

SHY125-315B

|

1450

|

170

|

23.1

|

18.5

|

30

|

37

|

|

SHY125-400

|

1450

|

200

|

50

|

55

|

75

|

90

|

|

SHY125-400A

|

1450

|

182

|

41

|

37

|

55

|

75

|

|

SHY125-400B

|

1450

|

170

|

36.1

|

37

|

45

|

75

|

|

SHY125-400C

|

1450

|

160

|

32

|

30

|

37

|

55

|

|

SHY150-250

|

1450

|

400

|

20

|

37

|

55

|

75

|

|

SHY150-250A

|

1450

|

363.5

|

16.5

|

30

|

37

|

55

|

|

SHY150-250B

|

1450

|

340

|

14.5

|

22

|

30

|

45

|

|

SHY150-315

|

1450

|

400

|

32

|

55

|

75

|

110

|

|

SHY150-315A

|

1450

|

363.5

|

25.5

|

45

|

55

|

75

|

|

SHY150-315B

|

1450

|

340

|

23.1

|

37

|

55

|

75

|

|

SHY150-400

|

1450

|

400

|

50

|

90

|

132

|

160

|

|

SHY150-400A

|

1450

|

363.5

|

41

|

75

|

90

|

132

|

|

SHY150-400B

|

1450

|

340

|

36.1

|

55

|

75

|

110

|

|

SHY150-400C

|

1450

|

320

|

32

|

55

|

75

|

90

|

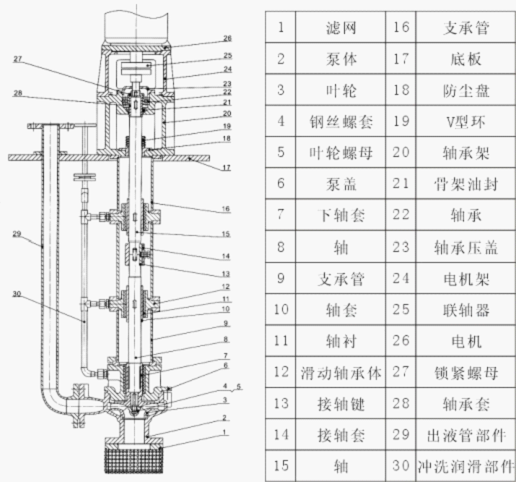

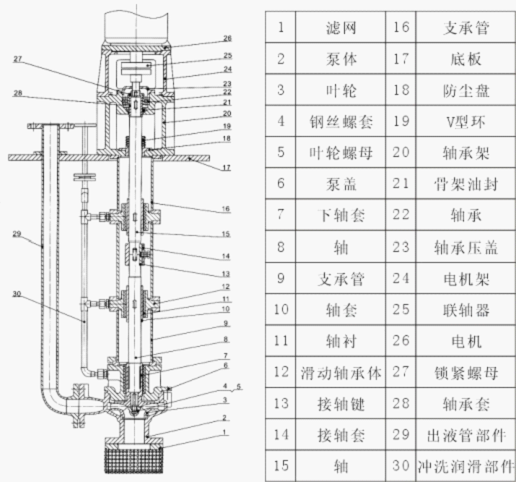

SHY液下泵结构示意图

SHY液下泵安装使用与维护

安 装

1、泵组装好后,盘动联轴器,看是否转动灵活,检查有无金属摩擦声。

2、检查泵轴和电机轴的同心度,两联轴器外圆上的差数不得超过0.3毫米。

3、轴衬需能浸在液体中,否则应自出口管路中引出(或从外部接入)适量液体,润滑轴衬,防止干磨损坏。

4、在化工流程系统中,若有杂物落入容器时,为防止杂物损坏泵体,可在吸入管处,装上所需形式的拦污网。

5、泵的吸入口到容器底部之距离为吸入口径的1.5~2倍,四周不应少于2.5倍,小口径取大值,大口径取小值。

6、泵之出液管路应加设支架支撑,其重量不允许加在泵出口法兰上。

7、安装完毕后,还需检查各螺帽是否旋紧,并应盘动联轴器,转动灵活后方可将泵和电机组装在容器上,装好后再检查一次。

起动与停车

1、检查轴承腔,使之保持有定量干净的黄油。通常以充满空腔容积的1/2~1/3为宜,避免运转时轴承温升过高。

2、盘动联轴器、检查有否轻重不均匀。否则需找出原因,待消除后再运转。

3、若采用外部冲洗润滑轴衬,在启动电机前需将外部液体通入轴衬中。

4、检查电机的转向,使之与泵的规定旋转方向相同。

5、关闭出口管路中的闸阀及压力表。

6、起动电机后打开压力表,慢慢的打开出口管路闸阀到所需位置,投入正常运转。

7、正常停车,应先慢慢关闭出口闸阀,然后停止电动机,关闭压力表。

8、长期停车或长期不用,应将泵从容器中取出,清洗、重装、加油保管。

运 转

1、轴承温度不得高于80℃,轴承盒内应有适量的黄油。

2、随时注意保证黄油的洁净。

3、泵运转过程中发生下列故障,应立即停车,并进行检修。

销售部

销售部